A Brushless DC motor with gearbox is used in appliances that require long life and low noise, such as textile machines and machine tools. Let’s find out how it works and what are its advantages.

A brushless DC (Direct Current) motor is a type of electric motor without brushes, a key feature that differentiates it from other DC motors. Given its composition, it does not require electrical sliding contacts to operate but uses permanent magnets to produce a rotating magnetic field.

The interaction between the input current circulating in the stator windings and the magnetic field generated by the rotor produces continuous rotation without direct contact.

The balanced rotating motion produced by this process makes it suitable for use in robotics, electronics and mechanical engineering.

Overview

Brushless DC gearmotors consist of a motor, a gearbox, and eventually an integrated encoder.

Coupling a gearbox with a brushless motor varies its speed according to the reduction ratio chosen. This allows use in various applications with different required speeds.

The presence of an integrated encoder makes it possible to detect the position and direction of rotation of the gearbox.

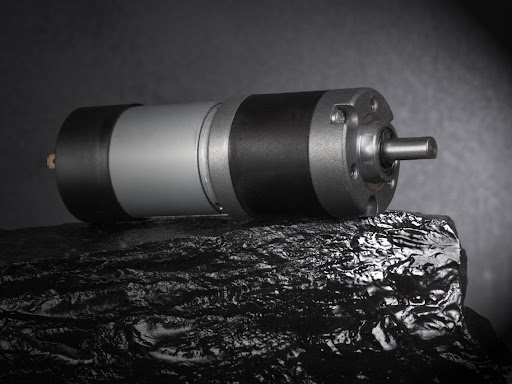

Micro Motors brushless DC motor with planetary gearbox

Micro Motors manufactures a series of brushless DC gearmotors with a wide range of gear ratios.

Series BL192

The Micro Motors BL192 series with brushless DC motor and planetary gearbox has a range of gearboxes with ratios from 3 to 625 and output speeds from 1360 rpm to 8 rpm.

Below are the main characteristics:

- Brushless gear motor with electronics on board

- Brushless motor 3 phase 12 pole with 3 hall sensors

- Outgoing shaft supported by two ball bearings

- Maximum radial shaft load: 200N (10 mm from the fixing flange)

- Maximum axial shaft load: 100N

- Temperature range: -10 °c/+50 °c

- Approx weight: 320/420g

Some features of brushless DC motors with gearbox

Micro Motors provide brushless DC motors with planetary gearbox with gear ratios ranging from 1:3 to 1:625 and a torque range from 15 Ncm to 300 Ncm.

Planetary gearboxes have some plus features compared with spur gearboxes:

- High reduction ratios

- High torques

- Significant output shaft loads

The advantages of using a brushless DC motor with gearbox

Brushless DC motors integrated with the gearbox are perfect solutions for motion control applications that require high precision, maximum efficiency and a small dimension, such as in automation and robotics.

The absence of sliding contacts is a major advantage in applications where the existence of sparks can be a disturbing element, and ensures a longer motor life as it is not subject to brush wear.

The presence of integrated electronics in our BL192 series gearmotor also makes it possible to adjust the motor speed, direction of rotation and start/stop making it more flexible and versatile to meet any market need.